Wind farms have become a cornerstone of renewable energy production, providing a clean, sustainable alternative to fossil fuels. However, the efficiency and reliability of wind farms are significantly influenced by weather conditions. Understanding these potential impacts is crucial for optimizing wind energy production and ensuring the stability of the power grid. In this article we will discuss different weather elements and how they can impact modern-day wind farms.

Wind

Since the displacement of air, which we perceive as wind, is the primary factor in wind farm efficiency it is the most obvious weather element to start with. Wind turbines are designed to operate within a specific range of wind speeds, known as cut-in and cut-out speed. So, when it comes to wind speed “the more, the merrier” is not really applicable within the industry, since there is a clear ceiling above which a turbine has to be shut down or simply can’t generate more power.

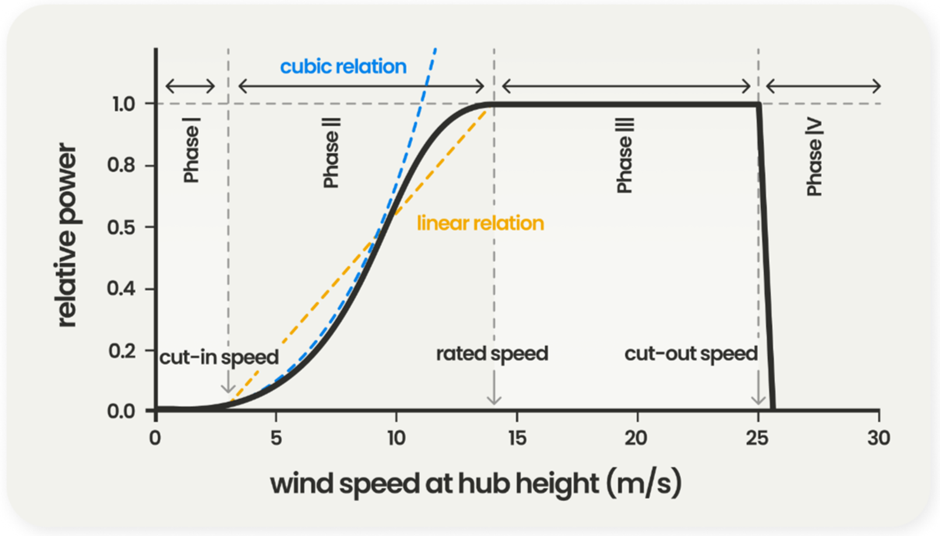

The performance curve of most wind turbines describes the relationship between the wind speed at the hub height and the electrical power delivered by the generator. A typical power characteristic curve of a single wind turbine is shown in Figure 1.

Figure 1

In phase I the wind speed is below the cut-in speed of the turbine. The minimum wind energy required to compensate for friction and inertial forces of the turbine is not met properly. Therefore, no electrical power is generated in phase I, and the turbine does not start.

In phase II the wind turbine is switched on and the conversion from kinetic (wind) energy into electrical energy starts. The power output increases with the wind speed. The rated power is reached at the turbine-specific rated wind speed, typically around 12–15 m/s. The power output in phase II can be simplified as a linear relation. However, the power curve of wind turbines is theoretically described by a cubic function of the wind speed at hub height. This cubic relationship is what makes wind speed such an important factor for wind power, as it is this dependence that cuts out at the rated wind speed. This leads to the relatively flat part of the curve in phase III.

Reaching rated speed

After reaching the rated wind speed, the power output remains at or just below its rated power in phase III. Stronger winds could lead to intense fatigue and extreme loads for the wind turbine generator system. Therefore, the rotor blades are automatically adjusted to the respective wind speed when the wind speed reaches or exceeds the rated speed. This adjustment is intended to limit the power output by means of appropriate different strategies, which typically include stall and pitch regulation controls, to prevent exceeding the rated generator power. The output curve could in real life therefore obtain a slight decline as a result.

In phase IV, when the wind speed exceeds the secured maximum wind speed value, the wind turbine is switched off. Even at extremely high wind speeds, no electrical power is generated. This cut-off wind speed usually lingers between 20 and 25 m/s, depending on the type of turbine.

So, when it comes to wind speed, there is a clear optimum for most wind farms. A good and reliable high resolution weather forecast can provide you with a powerful tool to optimize asset management.

Temperature

Most offshore wind farms are designed to operate in a temperature range of -10°C to +40°C but can be adjusted to handle temperatures up to -30°C. The power output of a turbine is related to density, which is a function of altitude, pressure, and also temperature. Dense air (which comes with lower temperatures) exerts more force on the rotors, resulting in a higher power output, even at relatively lower wind speeds compared to warmer and less dense air.

Source: ChelaseaGreen

Source: ChelaseaGreen

However, extreme cold can cause components to become brittle, increasing the risk of mechanical failures. All materials (steel, plastics, rubber seals, and even wiring and lubricants) need to be designed or adapted to withstand cold climates. The slow start-up of a wind turbine (loss of output) after idling in cold conditions is also a risky moment as the mechanical elements can be at risk because of insufficient lubrication and/or differential thermal expansion of the different components.

Conversely, extreme heat (if not combined with rather strong sustained winds) can cause overheating of the turbine’s electrical and mechanical components as well as lubrication systems, potentially leading to shutdowns and increased maintenance costs.

Humidity

Even though this weather element isn’t much thought of as a potential limiting factor, it is a noteworthy cause of corrosion for windfarms, especially of metal (mechanical) parts. For offshore wind farms salt water exacerbates this issue greatly compared to the wear and tear their onshore counterparts usually encounter. Regular maintenance and the use of corrosion-resistant materials are essential to extend the lifespan of turbines in such environments.

Also, it is known that the density of dry air is higher than that of humid air. Thus, humid air implies lower power output from a wind turbine if all other parameters remain unchanged. Moisture can condensate or attach onto turbine blades with largest condensate mass on the leading and trailing edges of the blades. This will inevitably lead to a thin water film, most pronounced in foggy/rainy conditions with large droplets and relative humidity close to 100%. Expensive coatings might mitigate this effect.

So, it would be the leading and trailing edge of the airfoil that are more receptive to contamination due to adhesion of insects, dust/sand or other airborne particles. Combined with low sub-zero temperatures icing is likely in the same zones as well. As a result, the aerodynamics change and drag increases, reducing the turbine’s performance.

Source: Rempel L., Rotor blade leading edge erosion-real life experiences, wind system magazine 2012

Source: Rempel L., Rotor blade leading edge erosion-real life experiences, wind system magazine 2012

Malicious weather

Severe weather phenomena such as thunderstorms, hurricanes and midlatitude wind events pose significant risks to wind farms as they can cause extensive damage. Hurricanes, with their combination of high winds and waves accompanied by torrential rainfall, can be particularly destructive over large areas.

Advanced design features, such as lightning protection systems and reinforced structures, are critical in minimizing damage from severe weather. Additionally, strategic placement of wind farms away from regions prone to extreme weather can reduce the risks.

Also, the importance of reliable weather forecasts and climatological data cannot be stressed enough in these situations. At Infoplaza we work around the clock on keeping our clients and their assets safe by supplying the highest quality weather forecasts and climatological data.

Like to read more of these insights? Subscribe to our marine newsletter: